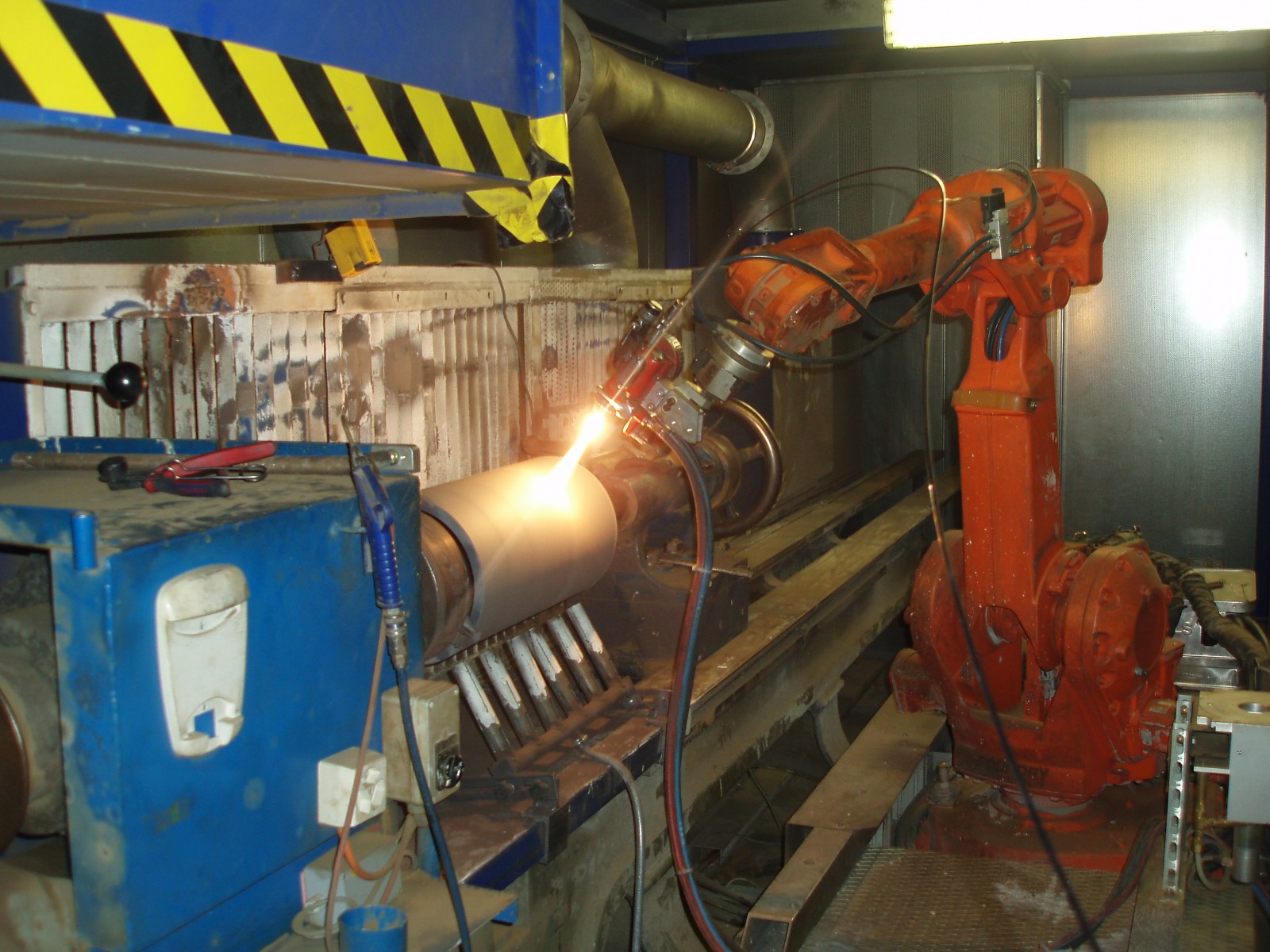

Since 1965 we have experience in the flaming technology. Today, we use newest robot technology in the spraying process with wire and powder. Metal spraying, mechanical engineering and sandblasting is our core business. We repaired already many complicated machine parts more economically with electric-arc spraying process, than this would have been possible with a new creation. When may we work on your parts?

Welcome to the coating specialists!

Now we can offer the following innovations to you

- HVOF coating

- Abrasive blasting area with a size of 6 x 3.5m

- Overhead crane for a max. weight of 5t

- Newest OSU-Hessler electric-arc spraying equipment

- Coating of rolls up to 4.5m length

- Coating of areas up to 4x2m

Make a sample order and see yourself the advantages of metal spraying!

Important advantages by using thermal coating processes

- No expensive new parts!

- Shorter time to market!

- No distortion of the workpiece!

- Interesting material mating (e.g. steel on aluminum)!

- Increase of the parts lifetime by high-wearing materials!

- Flexibility with onsite metal spraying and deposition welding!

- Repair is inexpensive

English

English Deutsch

Deutsch